At Vortex Systems, we stand at the forefront of aerospace engineering innovation. As the industry evolves, outdated equipment can hinder operational efficiency and compromise safety. Recognizing this potential pitfall, our team specializes in rejuvenating or replacing legacy systems. Through cutting-edge technology and engineering prowess, we seamlessly upgrade and optimize older equipment to meet and often surpass contemporary standards.

We also ensure that your team is fully equipped to leverage all software and hardware systems developed and manufactured by Vortex Systems to their maximum potential. Our comprehensive training process equips users with the knowledge and skills necessary to operate, calibrate, and maintain the sophisticated systems we develop and manufacture. The advanced software and integrated operator consoles we provide are designed to enhance the efficiency of your facility, featuring user-friendly self-diagnostic capabilities that streamline troubleshooting and ensure seamless operation.

Explore our diverse range of services and discover how we can elevate your aerospace operations to new heights. Our detailed imagery, showcasing both front and back views of our equipment, provides an insightful glimpse into how our innovations can revolutionize your aerospace operations.

Mechanical Design

When it comes to detailed visualization, our use of SolidWorks drawings stands out, offering clients clear and precise renditions of their bespoke cabinets and solutions. Collaboration is key in our approach, as we work hand-in-hand with our Programming group to refine data, ensuring that the information you receive is accurate and meaningful. Moreover, we don’t just focus on the parts—we also consider their environment ergonomic concerns. Our layout designs for rig test cells are carefully planned to eliminate any interference, while our internal building structure sketches are crafted with a critical eye on achieving the optimal placement of rigs. This holistic approach to mechanical design underlines our delivery of comprehensive solutions that encompass every aspect of the system’s physical framework.

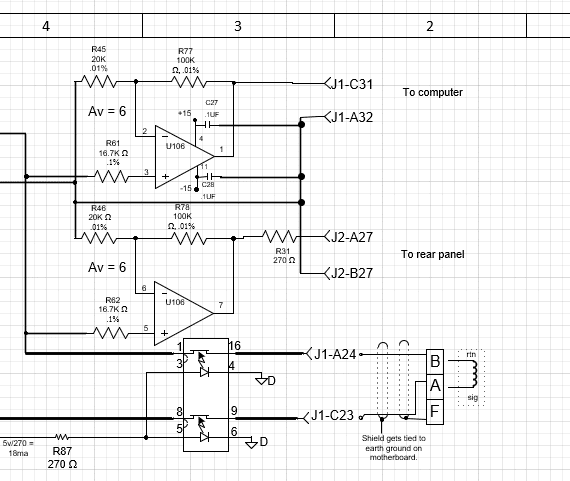

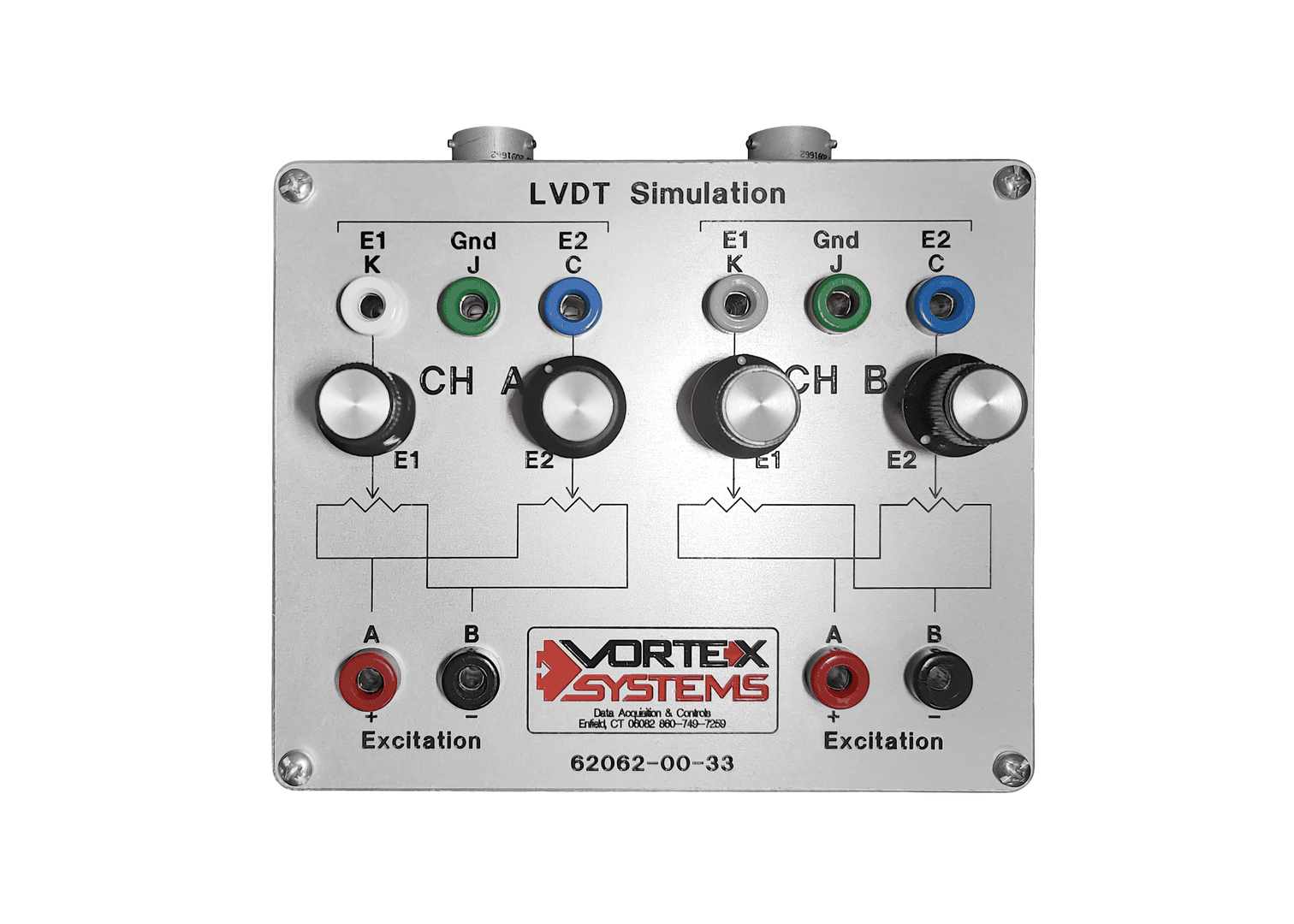

Electrical Design

In addition to circuit design, we bring ideas to life through our fabrication of printed circuit boards (PCBs). These PCBs are not just off-the-shelf; they are custom-designed and tailored to support a variety of torque motor and PWM solenoid types, thereby providing a perfect match for specific aerospace applications. Further complementing our electronic design prowess is our ability to create custom card cages which are engineered environments, equipped with our own circuit designs, that facilitate optimal operation and integration into broader systems.

Fabrication

Calibration

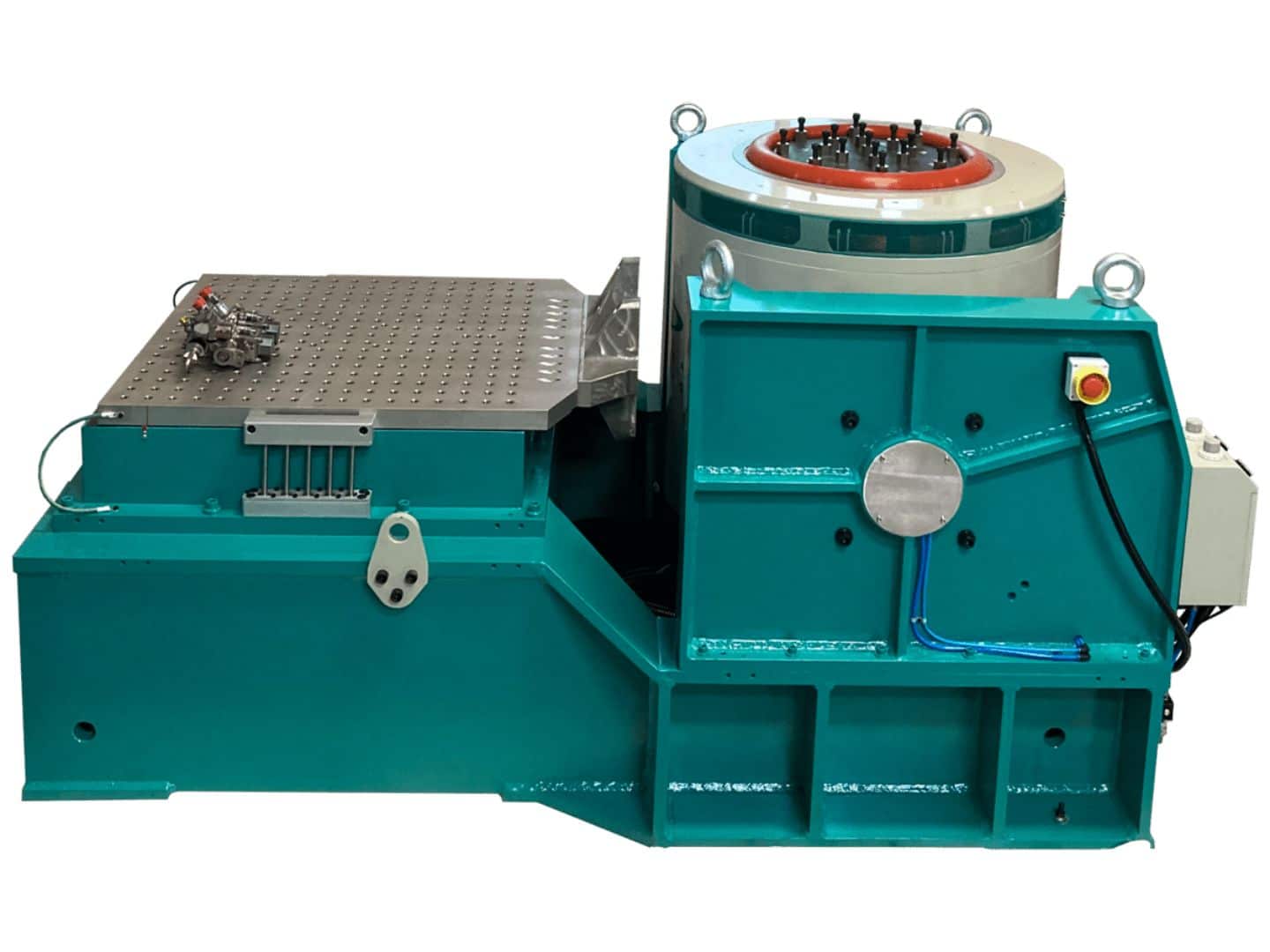

Hydraulic Test Stand

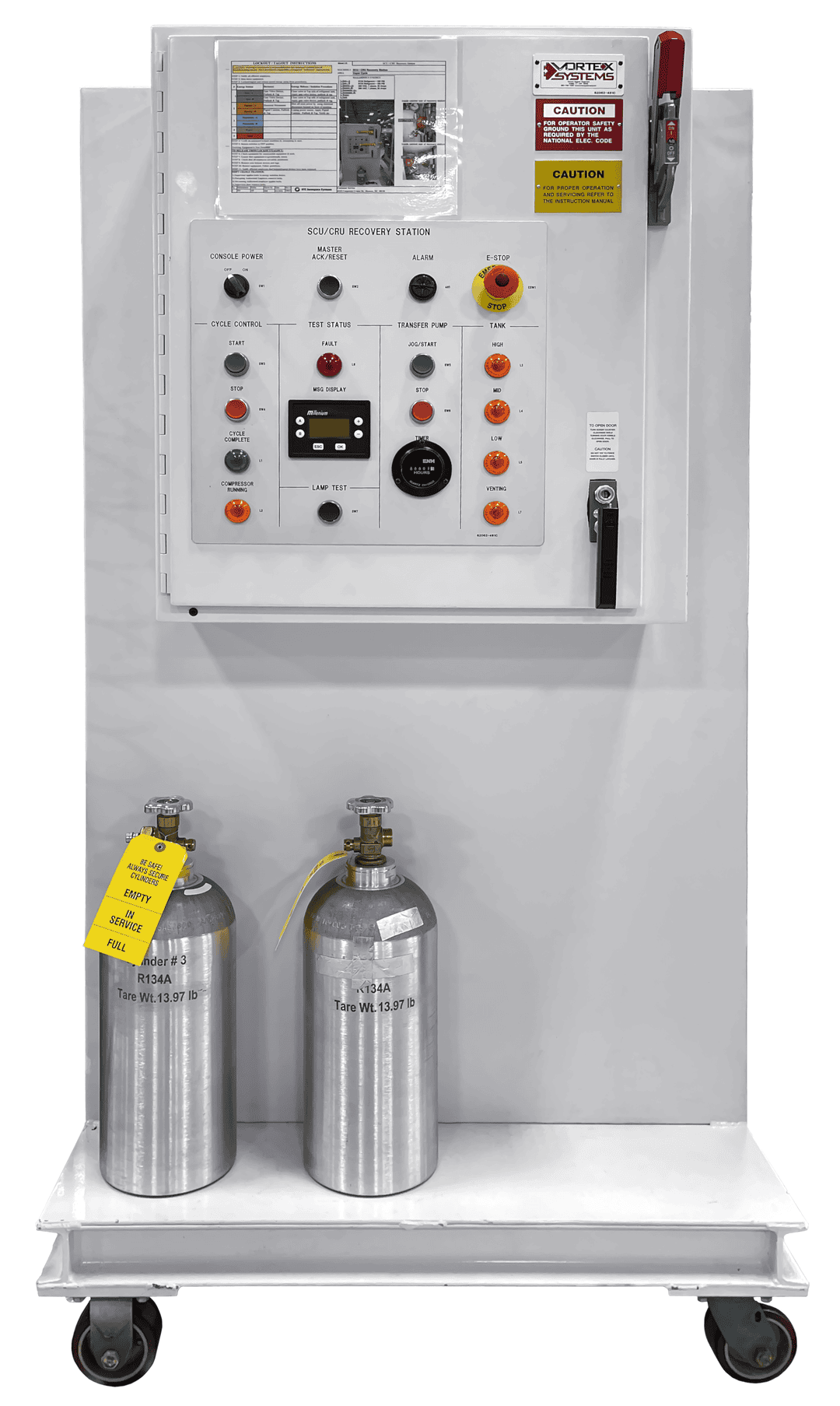

Pneumatic, Electro-Pneumatic Test Stand

Vortex Systems pneumatic testing services are designed to rigorously evaluate the performance of air / electric-driven components. We deliver an array of B787 aircraft component testing capabilities for both production and overhaul maintenance facilities including Air Cycle Machine, Cabin Air Compressor, Ram Air Fan, and Motor driven compressor to our customers worldwide to ensure efficient operation, which is crucial for maintaining the reliability of the systems that depend on them. From actuators to control valves, Vortex Systems guarantees that every pneumatic component we test will perform consistently under the varied and demanding conditions they will encounter in service. Our Rotative Leakage Cart is ingeniously crafted to pinpoint internal leakages within Boeing 787 aircraft components, enhancing maintenance efficiency. The Portable Air Valve Tester, equipped with intuitive front panel readouts and versatile rear panel outputs, precisely measures resolver positions in degrees and facilitates